The power loom revolutionized the textile industry. Operating on a simple principle, it weaves cloth automatically. How does the power loom work? Powered by a motor, the loom intertwines threads to create intricate fabrics swiftly. With its intricate mechanism, the power loom streamlines the weaving process, increasing efficiency and productivity. Let’s delve into this remarkable invention to understand its inner workings.

How Does the Power Loom Work?

Introduction to Power Looms

Imagine a machine that can weave beautiful fabrics quickly and efficiently. This incredible invention is known as the power loom. In this article, we will delve into the fascinating world of power looms and explore how these machines work their magic to create the fabrics we love.

History of Power Looms

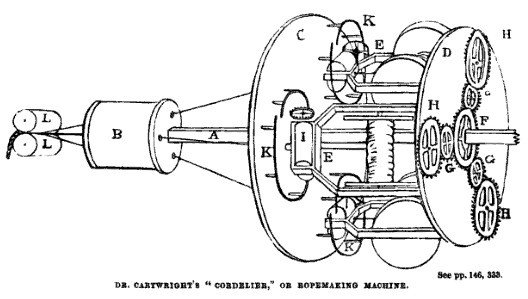

The power loom revolutionized the textile industry, allowing for faster and more consistent weaving than traditional handlooms. It was invented by Edmund Cartwright in 1784 and is considered one of the most important advancements in textile manufacturing.

Parts of a Power Loom

A power loom consists of several key components that work together to produce woven fabrics. These include the warp beam, heddles, reed, shuttle, and a mechanism for powering the loom.

The warp beam holds the lengthwise threads, known as the warp, under tension. The heddles are used to separate the warp threads, allowing the shuttle to pass through. The reed helps to push the weft thread tightly against the fabric. The shuttle carries the weft thread back and forth across the warp threads.

How Power Looms Work

To understand how a power loom works, let’s break down the process step by step:

1. Warping: The process starts by loading the warp yarn onto the warp beam. The warp yarn is the set of yarns that run lengthwise in the fabric.

2. Weaving: The power loom then lifts and lowers the warp threads using the heddles, creating an opening known as the shed. The shuttle containing the weft yarn passes through this shed, inserting the weft yarn across the warp.

3. Beating: After the weft yarn is inserted, the reed pushes it tightly against the fabric. This process is called beating.

4. Repeating: The power loom repeats this sequence rapidly, allowing for continuous weaving of the fabric.

The Role of Automation in Power Looms

Power looms have evolved over the years to become highly automated machines. Automation allows for precise control over weaving patterns and speeds up the production process significantly.

Benefits of Automation in Power Looms

Automation in power looms brings several benefits, including increased efficiency, reduced labor costs, and improved quality control. These advancements have revolutionized the textile industry and made it possible to produce a wide variety of fabrics in large quantities.

Modern Power Loom Technologies

Today, modern power looms are equipped with advanced features such as computerized controls, automatic shuttle changing systems, and sensors for detecting fabric defects. These technologies have further enhanced the speed and accuracy of weaving operations.

In conclusion, the power loom is a remarkable invention that has transformed the textile industry. By understanding how power looms work and the role of automation in modern machines, we can appreciate the intricate process involved in weaving fabrics. Next time you wear a piece of woven fabric, remember the incredible journey it took from a simple thread to a beautifully woven textile, all thanks to the power loom.

Primary, Secondary, and Tertiary Motion of Weaving Loom

Frequently Asked Questions

How is the power loom used in textile manufacturing?

The power loom is a machine used to weave fabric by automating the process of interlacing threads. It consists of a system of shuttles, heddles, and reed that work together to create the woven fabric. The power loom increases the speed and efficiency of weaving compared to traditional handloom weaving.

What is the role of the shuttle in a power loom?

The shuttle in a power loom is a component that carries the weft thread across the width of the warp threads. It moves back and forth between the layers of warp threads, interlacing the weft thread to create the fabric. The shuttle is a crucial part of the weaving process in a power loom.

How does the heddle mechanism work in a power loom?

The heddle mechanism in a power loom consists of frames with parallel wires or cords through which the warp threads are passed. By raising and lowering the heddles, the warp threads are separated into upper and lower layers, allowing the shuttle to pass through and weave the weft thread. This mechanism helps create the pattern and structure of the woven fabric.

What is the function of the reed in a power loom?

The reed in a power loom is a comb-like structure that keeps the warp threads evenly spread out and packed together after the weft thread is inserted. It also helps to beat the weft yarn into place, ensuring a tight and uniform weave. The reed plays a vital role in maintaining the quality and consistency of the woven fabric.

Final Thoughts

In conclusion, the power loom revolutionized the textile industry by automating the process of weaving fabrics. Its intricate mechanism involves multiple components working in harmony to create intricate patterns efficiently. Understanding how does the power loom work is crucial for appreciating its impact on mass production. With the power loom, intricate and precise designs can be produced quickly, enhancing productivity and quality in the textile manufacturing process.