To effectively grease ball joints, start by understanding the importance of this maintenance task. Properly greased ball joints ensure smooth operation and extend the lifespan of your vehicle’s suspension components. Regular greasing prevents wear and tear, reducing the risk of costly repairs down the line. Learning how to grease ball joints is a simple yet crucial aspect of vehicle maintenance that can make a significant difference in your driving experience. Let’s dive into the step-by-step process to help you keep your vehicle running smoothly for miles to come.

How to Grease Ball Joints: A Step-by-Step Guide

Welcome, DIYers, to our ultimate guide on how to grease ball joints! Ball joints are crucial components of your vehicle’s suspension system, responsible for allowing the wheels to move up and down while steering. Properly greasing ball joints can help extend their lifespan and keep your ride smooth and safe. In this comprehensive guide, we’ll walk you through the process of greasing ball joints like a pro. Let’s dive in!

Why Greasing Ball Joints is Important

Before we get into the nitty-gritty of how to grease ball joints, let’s understand why this maintenance task is crucial. Ball joints are constantly subjected to friction and heat, leading to wear and tear over time. Greasing helps lubricate the joints, reducing friction, minimizing wear, and preventing premature failure. Regular greasing also helps maintain the steering and suspension system’s integrity, ensuring optimal performance and safety.

Tools and Materials You’ll Need

Before you start greasing your ball joints, gather the following tools and materials:

Tools:

- Jack

- Jack stands

- Lug wrench

- Clean rags

- Grease gun

- Grease fitting cleaner

Materials:

- High-quality grease recommended for ball joints

Step-by-Step Guide to Greasing Ball Joints

Now that you have everything you need, let’s walk through the steps to grease your ball joints:

Step 1: Elevate the Vehicle

Use a jack to lift your vehicle off the ground and secure it with jack stands. Ensure the vehicle is stable before proceeding.

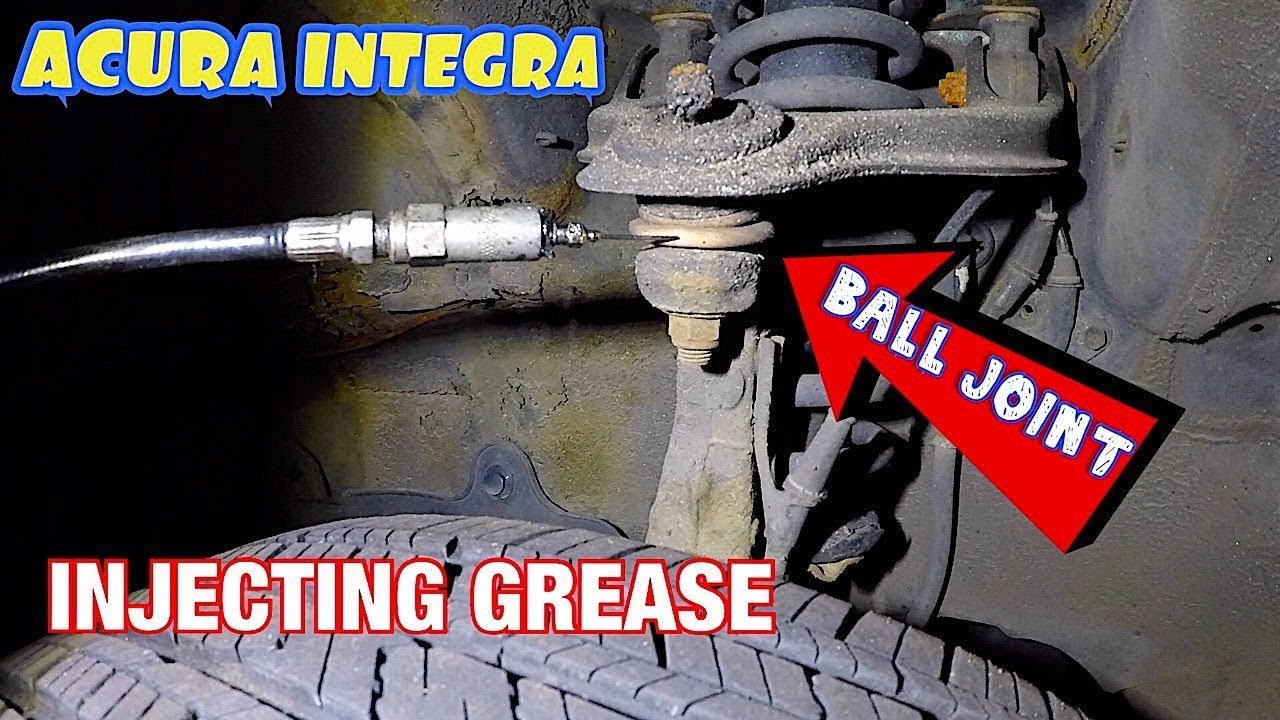

Step 2: Locate the Ball Joints

The ball joints are typically found where the control arms meet the steering knuckles. They have grease fittings that you’ll need to access for greasing.

Step 3: Clean the Grease Fittings

Before greasing, use a grease fitting cleaner or a small brush to remove any dirt or debris that might clog the fitting.

Step 4: Attach the Grease Gun

Attach the nozzle of the grease gun to the grease fitting securely to prevent grease leakage during the application.

Step 5: Apply Grease

Slowly pump the grease gun handle to inject the grease into the ball joint. Stop when you see fresh grease oozing out around the joint.

Step 6: Wipe Off Excess Grease

Use a clean rag to wipe off any excess grease around the joint to prevent attracting dirt and debris.

Step 7: Lower the Vehicle

Carefully lower your vehicle back to the ground and remove the jack stands. Test the steering and suspension by gently rocking the vehicle back and forth.

Maintaining Ball Joints: Best Practices

Now that you’ve successfully greased your ball joints, here are some additional tips to help you maintain them:

Regular Inspections:

Check your ball joints regularly for signs of wear, such as excessive play or noise. Address any issues promptly to prevent further damage.

Follow Manufacturer Guidelines:

Refer to your vehicle’s manual for specific recommendations regarding the type of grease and the frequency of greasing your ball joints.

Keep Grease Fittings Clean:

Regularly clean the grease fittings to ensure proper lubrication and prevent contamination.

Consider Professional Inspection:

If you’re unsure about the condition of your ball joints or how to grease them, consider consulting a professional mechanic for guidance.

Congratulations on mastering the art of greasing ball joints! By following our step-by-step guide and implementing the best practices for maintenance, you can keep your vehicle’s suspension system in top shape and ensure a safe and smooth ride. Remember, regular greasing and inspections are key to prolonging the lifespan of your ball joints and maintaining optimal performance. Happy greasing!

How to do a Chassis Lube (Ball Joints, Tie Rods Ends, and more!) | AnthonyJ350

Frequently Asked Questions

How often should ball joints be greased?

Ball joints should be greased every 30,000 to 50,000 miles or as recommended by your vehicle’s manufacturer. Regular greasing helps maintain proper lubrication and extends the lifespan of the ball joints.

What type of grease should be used for ball joints?

It is recommended to use a high-quality lithium-based grease for ball joints. Ensure that the grease is compatible with the specific conditions of your vehicle and provides adequate lubrication for the joints.

What are the signs that ball joints need greasing?

Common signs that ball joints require greasing include squeaking or creaking sounds when turning, excessive vibration, uneven tire wear, and poor handling. Regular inspection of the ball joints can help identify the need for greasing.

How can I access and grease ball joints on my vehicle?

To access and grease ball joints, you will need to lift the vehicle using a jack, locate the ball joints underneath the vehicle, clean the fittings, attach a grease gun, and pump grease into the fittings until you see fresh grease coming out. Make sure to follow the specific instructions for your vehicle model.

Final Thoughts

In conclusion, greasing ball joints is essential for maintaining smooth and efficient vehicle operation. To grease ball joints effectively, start by lifting the vehicle and cleaning the grease fittings. Then, use a grease gun to pump grease into the fittings until new grease starts to come out. Regularly greasing ball joints can prevent premature wear and extend the lifespan of your vehicle’s suspension components. Remember, knowing how to grease ball joints properly will help keep your car running smoothly for years to come.